Steel

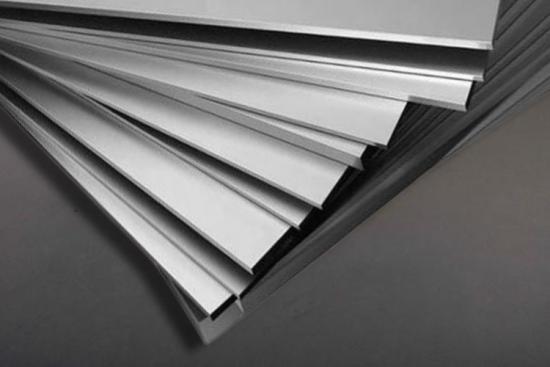

Steel is a widely-used material in CNC machining due to its excellent mechanical properties, such as high strength and durability. The type of steel employed depends on the specific requirements for each component - strength, hardness, and corrosion resistance included. Stainless steel is a popular choice for CNC machining due to its corrosion resistance and ability to remain strong at high temperatures. Tool steel also makes an excellent CNC cutting material due to its high hardness and wear resistance. Other steel types used in CNC machining include carbon steel, which is cost-effective and easy to machine; and alloy steel which has improved mechanical properties due to the addition of elements like chromium, nickel, and molybdenum. In conclusion, when selecting steel type for CNC machining it's important to take into account your component's requirements as well as any properties needed for final product. Material Tensile Strength (MPa) Yield Strength (MPa) Elastic Modulus (GPa) Hardness (HB) Advantages Applications 1018 Steel 440-790 370 190 126-183 Good machinability, low cost Bolts, nuts, studs, gears 1020 Steel 420-690 350 190 121-170 Good weldability, low cost Shafts, axles, pins 1045 Steel 585-800 330 205 163-229 Good strength and wear resistance Gears, shafts, bolts 4130 Steel 670-980 435 205 197-235 High strength-to-weight ratio, good weldability Aircraft parts, bicycle frames 4140 Steel 655-1065 415 205 197-235 High strength, toughness, and wear resistance Gears, axles, shafts 4340 Steel 745-1130 470 205 201-269 High strength, toughness, and fatigue resistance Aircraft landing gear, crankshafts A2 Tool Steel 670-1280 360 190 217-235 High wear resistance, good toughness Punches, dies, cutting tools A36 Steel 400-550 250 200 70-80 Easy to machine, weld, and form. Affordable and widely available. Structural applications, including buildings, bridges, and machinery. D2 Tool Steel 1700-2200 1200-1400 190-210 60-64 High wear resistance and toughness. Holds an edge well. Cutting tools, knives, shear blades, and dies. S7 Tool Steel 1600-2000 1400-1700 190-210 50-60 High impact resistance and toughness. Tooling applications that require shock resistance, such as hammers, punches, chisels, and shear blades. 303 Stainless Steel 620 - 860 260 - 420 190 160 - 180 Good machinability and corrosion resistance Aerospace, automotive, food processing, and medical industries 304 Stainless Steel 515 - 1035 205 - 515 193 70 - 92 Corrosion resistance and high-temperature strength Chemical processing, food processing, and medical industries 316 Stainless Steel 515 - 1035 205 - 515 193 70 - 90 Superior corrosion resistance and high-temperature strength Chemical processing, food processing, and medical industries 416 Stainless Steel 550 - 860 275 - 485 200 262 - 302 Good machinability and wear resistance Aerospace, automotive, and manufacturing industries 15-5 PH 1100 - 1380 860 196 363 - 388 High strength, toughness, and corrosion resistance Aerospace, chemic...

Read More